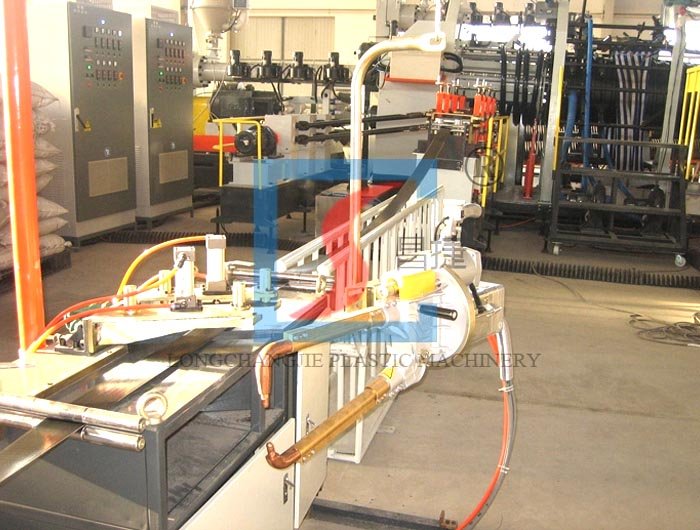

The extrusion line is mainly for producing large diameter hollow wall winding pipe ,Large diameter inding pipe (inner diameter from 50mm-2200mm) has high ring stiffness and high brunt intensity with structure It can be used for approxmate 50 years and hasmany advantages such as low cost assembly and easy operation ,ithstanding pressure corrosion resistant such as acid alkali and salt etc ,It is becoming as replacement of cement pipe and cast iron pipe nowdays Its beling widely used as sewerage and drinage pipe.

Production Line Features:

| Model | KFYPG-800 | KFYPG-1200 | KFYPG-1600 | KFYPG-2200 | KFYPG-3000 |

| Extruder Type | KFYSJ-65*30 | KFYSJ-50*30 | KFYSJ-65*33 | KFYSJ-50*30 | KFYSJ-80*33 | KFYSJ-50*30 | KFYSJ-90*33 | KFYSJ-65*33 | KFYSJ-100*33 | KFYSJ-65*33 |

| Output(kg/h) | 250 | 120 | 300 | 120 | 500 | 150 | 750 | 250 | 900 | 300 |

| Pipe specification(mm) | 200-800 | 400-1200 | 800-1600 | 1200-2200 | 2000-3000 |

| Production Speed(m/h) | 2-16 | 2-12 | 1-6 | 0.5-5 | 0.3-3 |

| Installed Power(kw) | 180 | 250 | 300 | 400 | 500

|

The extrusion line is designed with adventaged technologedHigh speed and excellent extrusion quality by adopting two sets of single screw extruder with high efficiency prformance Unique design of composite diedead for large diameter winding pipe processing with poducessing with high production effeciency ,High quality of winding pipe produced by adopting the unique winding process Easy operation and high performance by adopting an andvanced PLC

1.resistance pressure,good impact.inside of pipe u type steel belt can substantially improve the pipe ring stiffness.

2.good nconomy .light weight transport,installation easy ,the price is cheaper.

3.resistance PH,Aging,not corrosion by sewage and chemistry,black pipe UV,extended uselife.

4.drainage ,sewage clear,inside of pipe small resistance,ablity to pass water strong,flow big.

5.connection safe reliable,can use the electric hot-melt,shrinnk belt,inside and outside welding and so on combination,connect firm,the pipe no leakage.